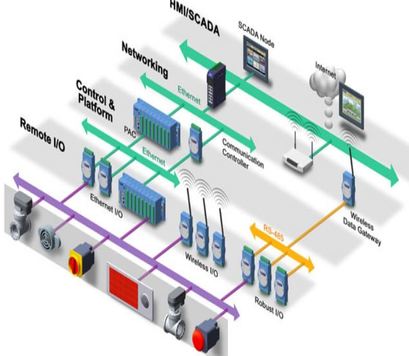

Our team of engineers have vast experience in industrial communications protocols. We are able to solve all forms of industrial communications challenges for our clients

Our team of engineers have vast experience in industrial communications protocols. We are able to solve all forms of industrial communications challenges for our clients. Whether it is legacy communication protocols or proprietary communication protocols such as (serial protocols e.g. CAN, Devicenet, DH+, Profibus, MPI, e.tc), industrial de-facto protocol e.g. Modbus, Fieldbuses such as H+ we are able to resolve any challenges you might have. Contact us today for your industrial communication and connectivity solutions.

RELIABLE, SECURE SEAMLESS CONNECTIVITY

Communication and connectivity is the backbone of efficient plant operations. Industry 4.0 and internet of things is providing more channels of improvement with more requirements for stringent security and communication reliability. We offer our clients solutions for seamless industrial connectivity.

Contact us today if you have the need to:

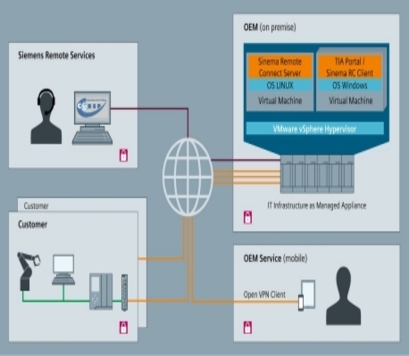

REMOTE MAINTENANCE SERVICES

CAS systems supports her client to achieve minimized downtimes and cost of maintenance via remote services support. Our clients soon reap benefits of innovative, secure, and seamless connectivity solutions provided by us, in terms drastic reduction in downtime and cost of maintenance. Our support programs connect you with the experts, reports, tools, and maintenance services you need to extract maximum life cycle value from automation hardware and software. Our solution provides cybersecure connection, programming tool to diagnose and troubleshoot equipment (HMI, PLC, or Drive) as if you are on site. CAS systems experts are able to provide remote maintenance troubleshooting, diagnosis, program, migration, upgrades, and disaster recovery support for our clients.